What Diesel Engine Starting System Major Structural Components?

The capacity of a starter motor generally ranges from 0.6 to 10 kW. When selecting a starter motor, it is necessary to purchase one with a corresponding power rating based on the diesel engine's power class , starting torque, and other conditions. The diesel generator set operation manual specifies the required starter motor specifications. Key Point: The voltage of the starting battery is typically 12V or 24V. It is essential to equip the battery with the corresponding voltage level and sufficient capacity as required by the starter motor.

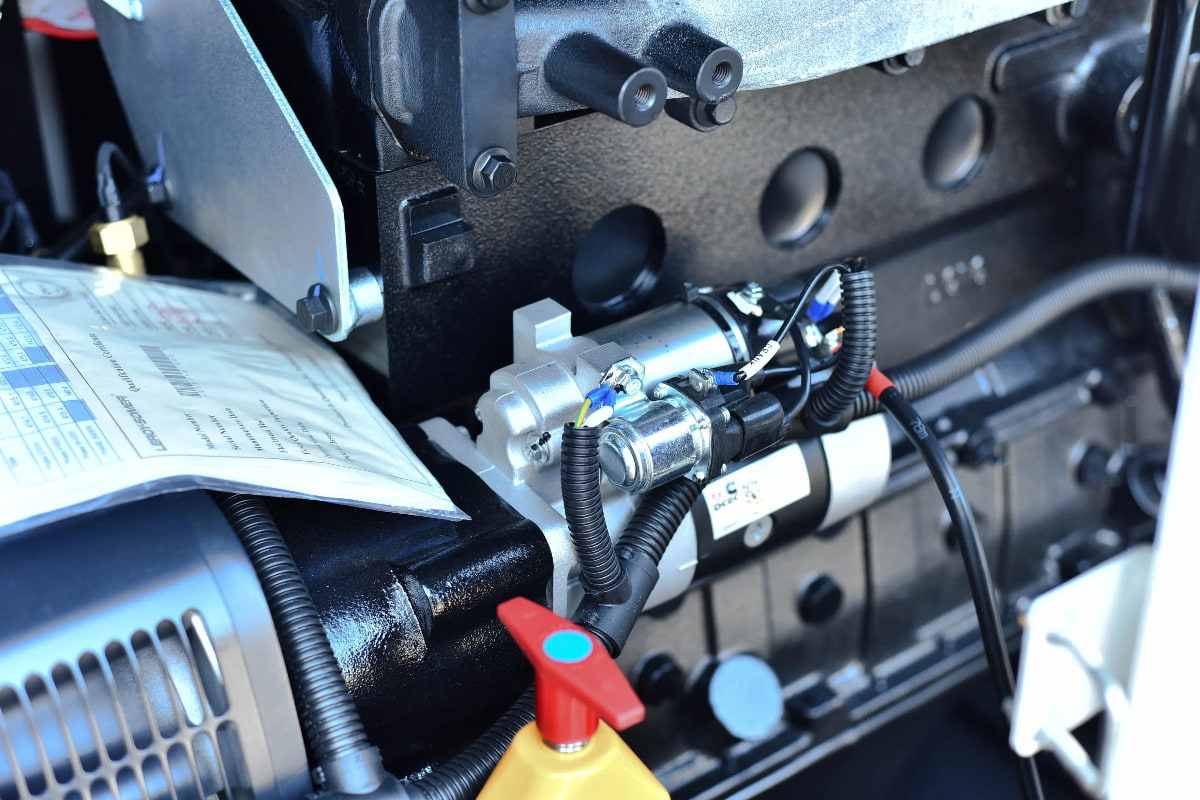

When the operator presses the start button of the electric starting system, the electromagnetic switch is energized and engages, controlling the starter motor and its pinion gear to mesh with the flywheel ring gear, thereby cranking the diesel engine for startup. The engagement gear on the starter motor shaft only meshes with the flywheel ring gear on the diesel engine's crankshaft during startup. Once the diesel engine reaches starting speed and begins to run, the starter motor must immediately disengage from the crankshaft. Otherwise, as the diesel engine speed increases, it would cause the starter motor to rotate at a greatly overspeed, generating excessive centrifugal force and leading to failure. Therefore, the starter motor must be equipped with a clutch mechanism. The starter motor consists of a DC motor, a clutch mechanism, and a control switch.

The DC motor is the prime mover that outputs torque. Its construction mostly employs a four-pole series-wound motor. This type of motor provides high torque output at low speeds and possesses strong overload capability.